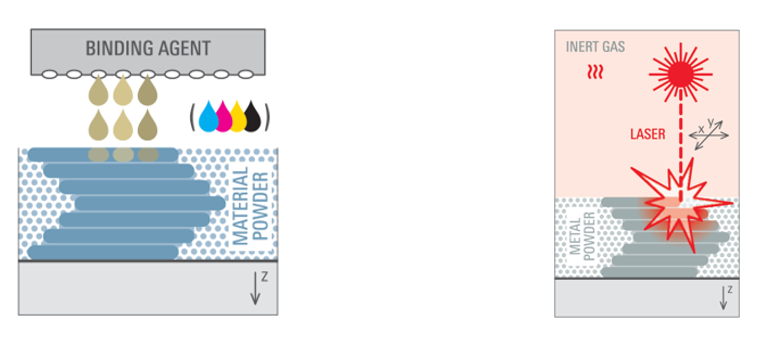

With 3D Metal Printing we offer you two different options, to produce a 3D printing component.

| Binder Jetting (BJ) | Selective Laser Melting (SLM) |

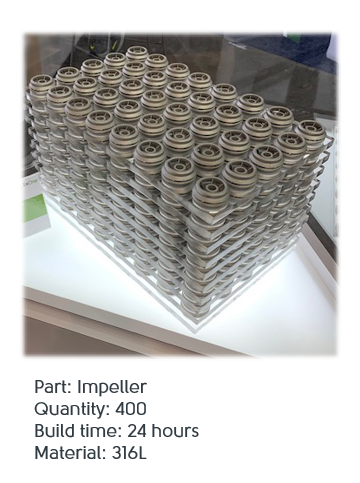

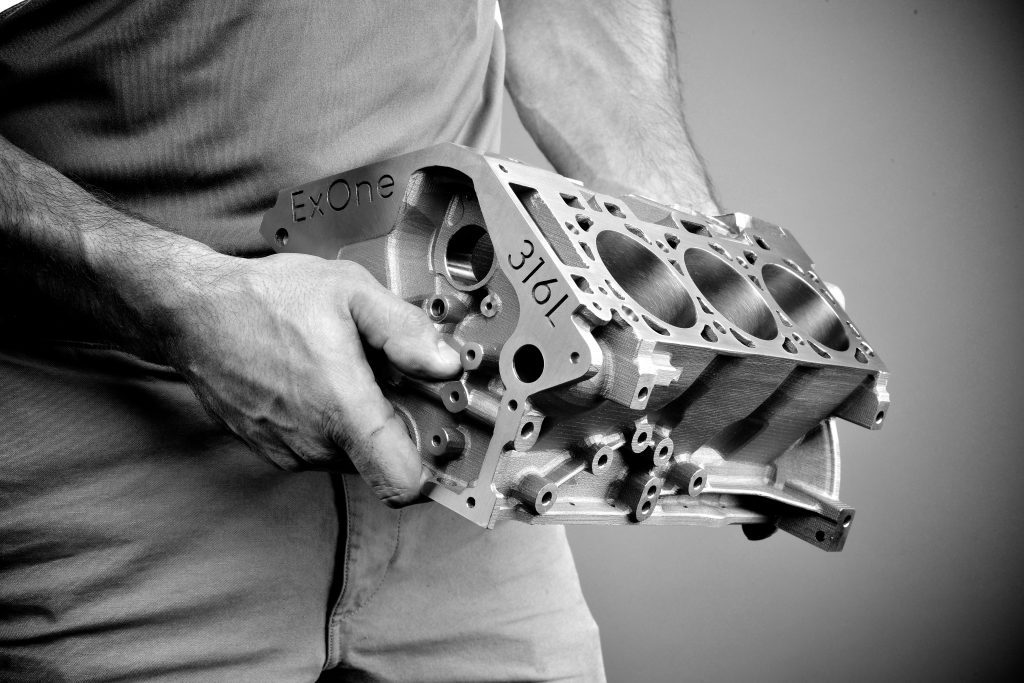

| The binder jetting process involves the selective application of binder droplets to the metal powder, causing the powder to stick together. Then, after initial hardening, a sintering process is required to achieve the material properties. The shrinkage associated with the process is now solved in a process-safe manner. The productivity of the BJ process is significantly higher than the SLM process. By optimizing the “job”, the piece time is minimized. For example an impeller: With complex inner contour, cycle time of 3 minutes. | In the SLM-process, the metal powder is melted layer by layer by means of a mobile laser beam as it is applied, producing the cross-section of the component. The following process steps must be taken into account: * Support aids required to ensure dimensional accuracy, therefore reworking necessary * Delay is to be expected due to heat Input * Heat treatment always required – voltage due to welding process |

Source: Ritter, Steffen (2019). Formnext AM Field Guide 2019. Frankfurt am Main: Mesago Messe Frankfurth GmbH. ISBN 978-3-9820318-8